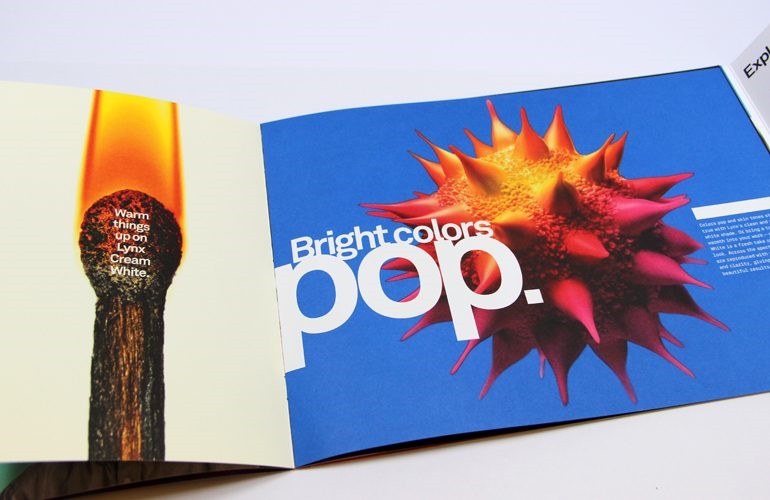

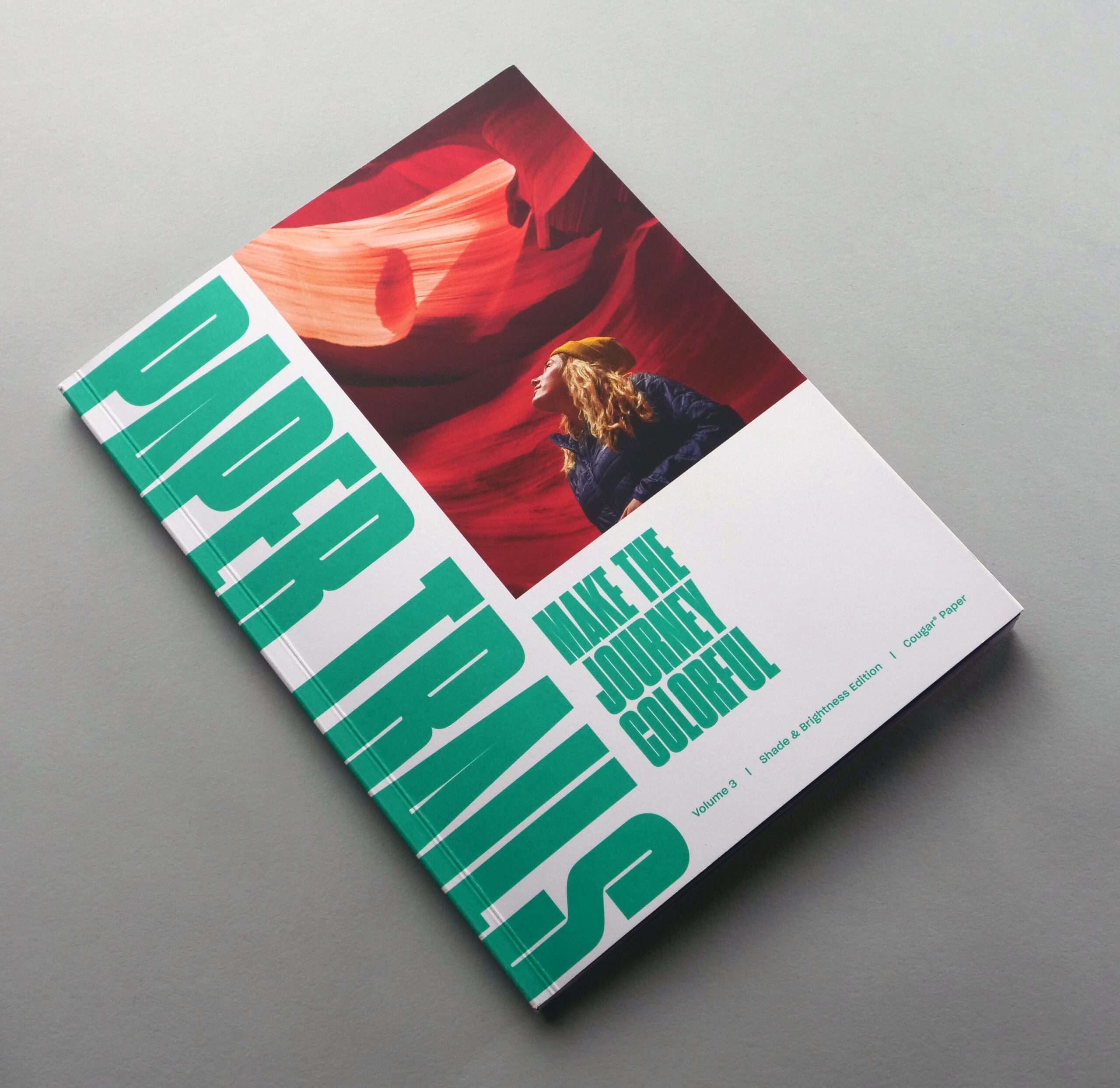

Here at Domtar, we receive countless print production questions on how we get our Cougar® and Lynx® Opaque Ultra uncoated paper promotions to look flawless. The good news is, we’re committed to printing without trickery: all of the results we achieve can be reproduced using one of our high-quality uncoated papers and conventional printing equipment. With our insider tips, you too can achieve beautiful reproduction of color and detail.

How can I prevent ink mottle with large blue solids?

I get questions about preventing ink mottle regularly. You’re printing a job with large areas of heavy coverage in blues or purples. The rest of the job looks great, but the blue tones are looking mottled and streaky. Can this be fixed on press?

Print mottle on uncoated papers can be caused by back trapping — when ink laid down in the first two print units is pulled unevenly from the already printed sheet by the blankets in subsequent units. Cyan can be challenging with respect to ink mottle; consider changing the ink rotation to reduce, or even eliminate, ink mottle. Most presses are set up with a standard ink rotation of KCMY. Moving cyan to the last unit in the rotation will produce a much smoother ink lay.

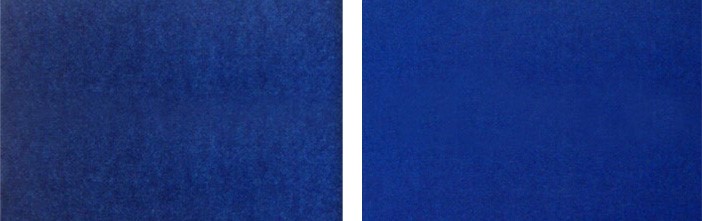

The image below was printed on a press that had extra ink units that were not being used. Leaving the second unit open, the pressman moved cyan to the fifth unit without touching the other inks — significantly improving uniformity. It’s a great way to solve a problem without sacrificing print quality.

The image of the left shows a “standard” ink rotation (K, C, M, Y), while the image on the right show a “modified” ink rotation (K, open, M, Y, C).

To receive more print solutions, print industry trends and graphic design inspiration, subscribe to our Paper Matters magazine.