You’re printing a job with large areas of heavy coverage that are in shades of blue or purple. The rest of the job looks great, but these blue tones are looking mottled and streaky. What’s going on and how do you fix this while on press?

Since the rest of your solids and color builds look good, you may be experiencing back-trap mottle. Back-trap mottle occurs when the Black (K) and Cyan (C) ink laid down in the first two units of the press are partially taken back off the paper on the Magenta (M) and Yellow (Y) units (in your standard KCMY ink rotation). The ink is not removed uniformly and thus creates a mottled look. How can you tell if this is happening? Quite simply, ask the pressman to take all but the Black and Cyan units off impression. Your color may be different than the hue of your final image, but you should be able to see quickly if the ink uniformity has improved.

Since the rest of your solids and color builds look good, you may be experiencing back-trap mottle. Back-trap mottle occurs when the Black (K) and Cyan (C) ink laid down in the first two units of the press are partially taken back off the paper on the Magenta (M) and Yellow (Y) units (in your standard KCMY ink rotation). The ink is not removed uniformly and thus creates a mottled look. How can you tell if this is happening? Quite simply, ask the pressman to take all but the Black and Cyan units off impression. Your color may be different than the hue of your final image, but you should be able to see quickly if the ink uniformity has improved.

OK. You can see that the ink uniformity is much improved. Now, what do you do? You certainly can’t print with just 2-colors on your 4-color job! Cyan ink tends to be more prone to back-trap mottle than other colors. Although it may be a little time-consuming for the pressman, the best solution is to change the order of the ink rotation. Most presses are set up with a standard ink rotation of KCMY. By moving the cyan ink to the last unit in the rotation, you can significantly improve the overall lay of the ink on your print job.

OK. You can see that the ink uniformity is much improved. Now, what do you do? You certainly can’t print with just 2-colors on your 4-color job! Cyan ink tends to be more prone to back-trap mottle than other colors. Although it may be a little time-consuming for the pressman, the best solution is to change the order of the ink rotation. Most presses are set up with a standard ink rotation of KCMY. By moving the cyan ink to the last unit in the rotation, you can significantly improve the overall lay of the ink on your print job.

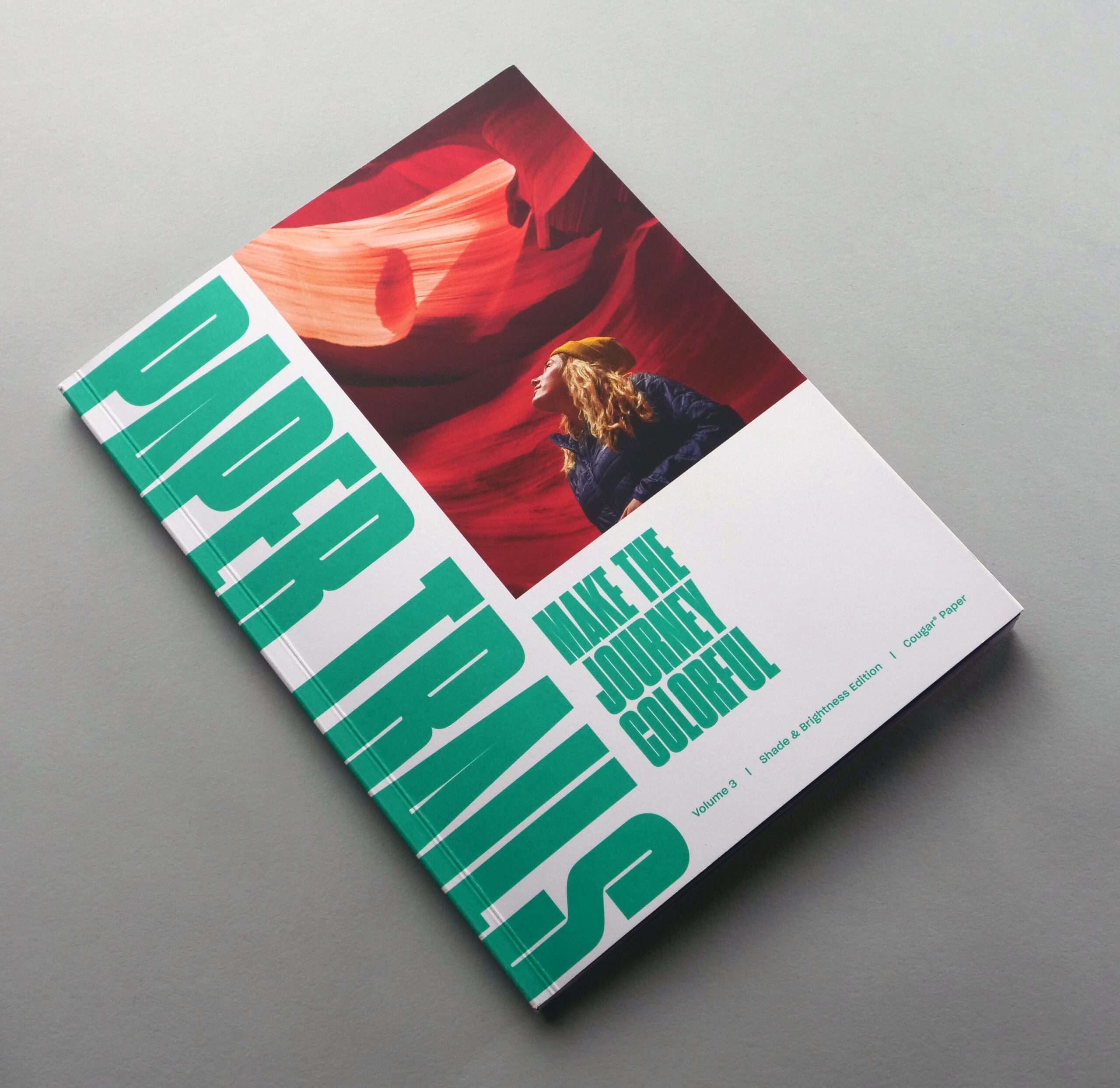

The image above was printed on a press that had extra units that were not being used for the job. By leaving the second unit “open”, the pressman was able to move the Cyan to the 5th unit and not have to move the rest of his ink colors. And…..the uniformity of the ink lay was significantly improved! Many printers don’t hesitate to modify their ink rotation when they see this type of mottle. Changing the ink rotation may be the way to salvage your job without sacrificing print quality.