Printing with metallic inks is nothing new in the print and design world; however, achieving stellar results when it comes to print design often requires a combination of things. One cannot produce good print results with good design alone – although certainly it is an essential component. But producing noteworthy print usually involves a team of active participants.

Collaboration regarding production design can save a ton of time and expense, not to mention improve overall print goals. This is especially true when looking to incorporate a new print technology, like digital metallic inks, into your work.

By now creatives are well aware of digital printing and its ability to produce solid print results with low quantities and quick turnaround times. Yet for many creatives, they often find it lacking in terms of special effects, especially when compared to what can be produced offset. But printers are a resourceful bunch and quite adept at utilizing the full strength of the technology available to yield impressive results.

Early on with digital print technology, to achieve the look of digital metallic inks many printers got creative with the papers available and produced four color digital print results on metallic papers in lieu of using metallic inks. This worked for a bit, but creatives are a sophisticated bunch and there’s no substitute for the real deal.

By continuing to push for solutions for their creative clients, printers helped drive demand in the advances in technology for printing metallic inks by the OEM’s. Now designers have a few options for producing gold and silver metallics on digital print projects – and they have their printers in part to thank for it.

Kodak was the first to introduce a metallic “ink” offering for its NexPress a couple years back. Gold dry ink offers metallic gold and a series of metallic effects to heighten impact and creativity. And as my print rep pointed out, when printed on top of another color, Gold Dry Ink can be used to simulate a variety of metallic effects including copper and bronze. I never would’ve thought to layer the technology to achieve different metallic colors.

More recently, Xerox introduced metallic dry inks for the ColorPress using true PANTONE metallic gold and silver inks! What makes this technology truly amazing is the fact that there’s actual gold and silver flecks in the dry ink. This part is important because it determines the amount of “flop,” the reflective rate of the metallic effect. Who knew? My print rep, that’s who. And the best part, it doesn’t require multiple clicks to achieve the desired metallic results.

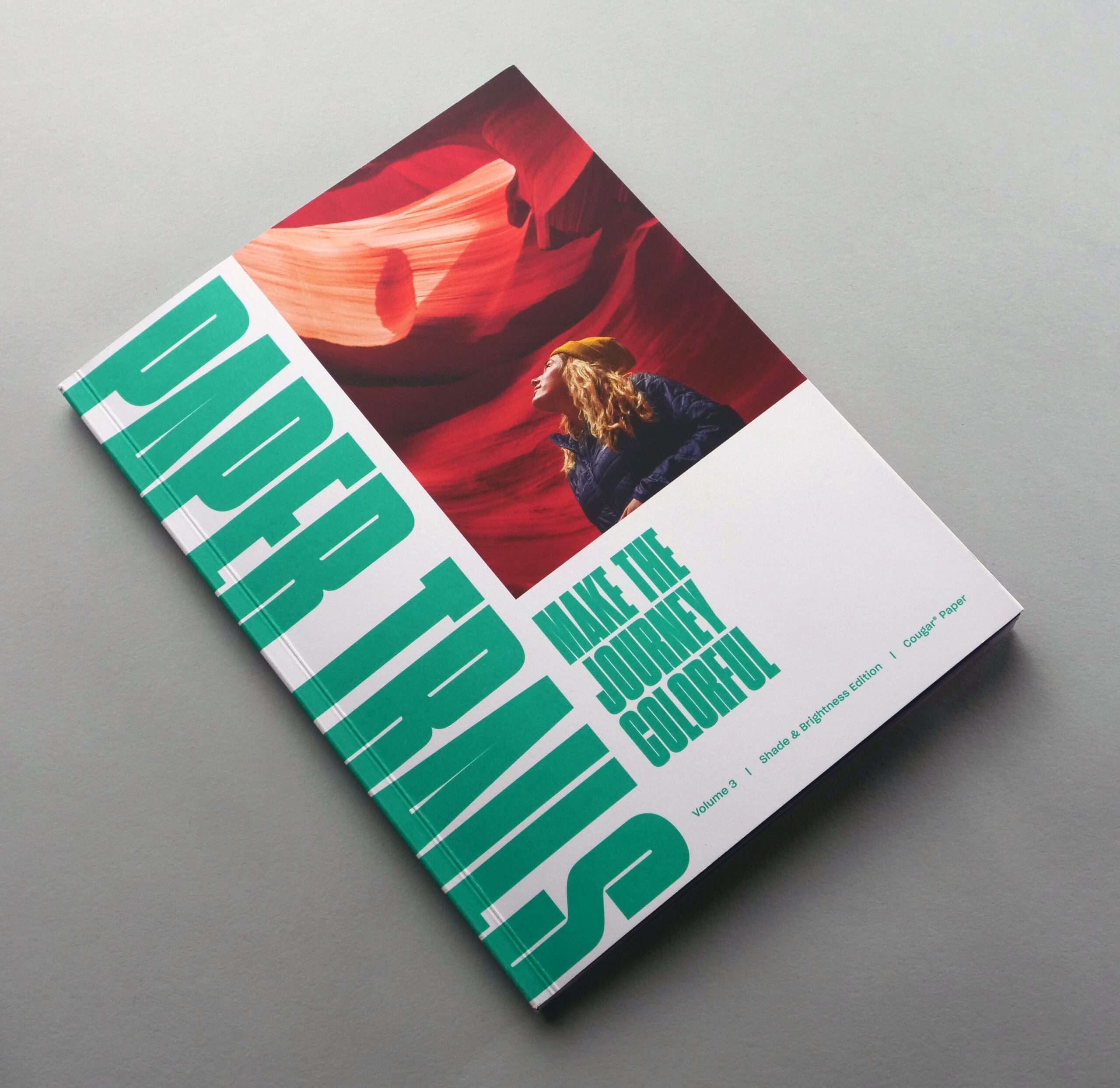

Check out these results using digital metallic gold ink in Domtar’s Make Your Mark promotion. These pieces were produced on a Xerox ColorPress and look as good as any metallic inks I’ve seen produce using offset litho.

Yet, even with all the advances in technology it doesn’t mean digital is always the most effective way to go. Your print rep’s job is to help you determine the best way to produce a print project. Ask them about the available technology and what their capabilities are. When it comes to using metallic inks, reps will look at the most cost effective way to produce the project and give you the results you want.

And the really good reps will tell you if they’re not a good fit for a particular project and often recommend someone who is. After all, they’re not looking to make a transaction; they’re looking to collaborate with you to produce great work on an ongoing basis.