Full-Cost-of-Water Model Contributing to Conservation Efforts

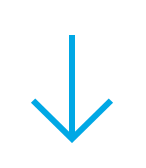

Water is essential to pulp and paper production – our mills use it to wash and transport pulp, dilute and prepare process chemicals, make steam and electricity, carry raw materials through the mill and clean and cool equipment.

All of our mills are located in watersheds with ample water supplies. While we have access to abundant water supplies today, we don’t take this resource for granted.

When we consider the cost to pump, filter, chemically treat, demineralize, heat, reuse and clean the water again before we return it to the watershed, we are reminded that water is anything but free. That is why we spent the past few years working together with our environmental, finance, energy and mill operations teams to develop a model to quantify the “full cost” of using water in our pulp and paper manufacturing processes.

Understanding the site-specific cost of using water helps us to better focus our efforts and resources on conservation in areas where they will do the most good. It also helps make the case for water, energy and resource conservation projects that previously may not have been funded using traditional return-on-investment calculations and models.

Domtar has used our full-cost-of-water model to support recent investments in water-related projects at two mills:

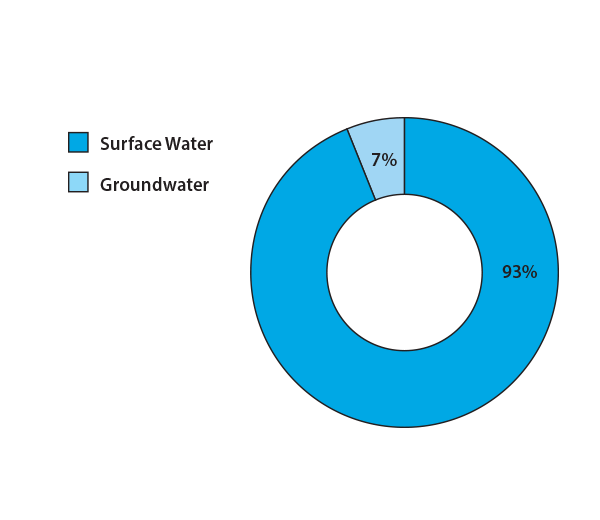

Reductions in Discharges to Water from Pulp and Paper Mills since 2016

Adsorbable Organic Halides (AOX)

-13%

Total Suspended Solids (TSS) -23%

Biochemical Oxygen Demand (BOD) -15%