Developing a Path to Carbon Neutrality

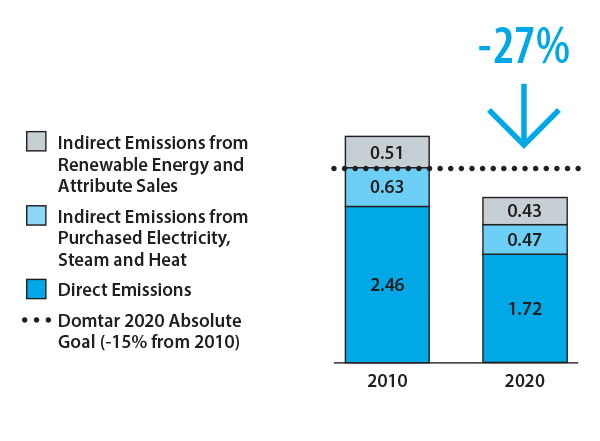

Reduction of greenhouse gas emissions has long been a focus of Domtar. The company’s pulp and paper mills have achieved a 27% reduction in total direct emissions and indirect emissions from purchased energy since 2010, surpassing our goal of a 15% reduction by the end of 2020. These reductions were largely achieved through fuel switching to carbon-neutral and lower carbon-intensive fuels (i.e., coal to natural gas), energy and operational efficiency projects, a greener electrical grid, and in 2020, lower production output. While these efforts have positioned Domtar well for a lower-carbon economy, we realize more needs to be done.

Changes will be required in both the short and long term to achieve international climate goals that an overwhelming majority of scientists and governments agree need to be met to minimize the worst effects of climate change. Domtar is committed to being at the table and doing our part to tackle this global issue – one that will require transformative changes to social, economic and environmental systems. We expect these changes will present us with both opportunities and challenges.

To that end, Domtar has begun evaluating pathways and developing plans to understand what “net zero” by 2050 would mean for our business. This requires a holistic strategy that considers what products we make, how we manufacture them, our supply chain, our governance and financial systems, research and development for new technologies, along with cooperation with policymakers and governments for sustainable climate mitigation frameworks.

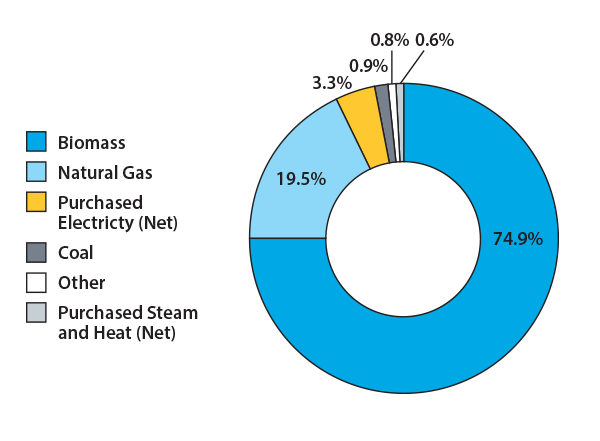

73% renewable energy used in our pulp and paper mills.*

Industry average = 65%.**

An equivalent of 71% of the electricity used in our pulp and paper mills was self-generated.

Industry average = 55%.**

27% reduction in total direct greenhouse gas emissions and indirect emissions from purchased energy at our pulp and paper mills since 2010.

* Net of renewable energy and attribute sales.

** 2020 American Forest & Paper Association Sustainability Report Additional Environmental Indicators